Metallic Labels Engraved 4 Color Printed New Logo No MOQ

Send InquiryThickness(mm): Customized

Shapes/outline: Customized shapes(Irregular available)

Size/Dimension: Customized

Finish: Laser marking/engraving

Serial numbers: Customized

Fixing: Holes/Self-adhesive

MOQ: 500pcs for custom design

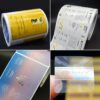

Metallic Labels Permanent Adhesive Custom Metal Label Plates

- Metal signs are ubiquitous symbols in our daily lives, and their presence can be found in many products or places; For example, mobile phones, computers, various electronic digital products, household appliances, gift box packaging, luggage, various leather goods, billboards, indicator signs, and so on.

- For example, the label decoration of electronic products, household appliances, luggage, gift boxes and other products highlights the cultural concept bestowed on the products by the enterprise and a quality hint given to customers, making people think of the enterprise and the products produced by the enterprise at the sight of the trademark.

- Metallic labels can add a touch of sophistication and luxury to your products, making it stand out and enhancing its perceived value. They are commonly used in high-end fashion items, luxury accessories, and premium consumer goods. The customized matallic labels allow to imprint your brand identity onto the product, in order to strenthen your brand recognition and loyalty among customers.

Metallic Labels Engraved 4 Color Printed New Logo:

|

Custom Printed Metallic Labels Permanent Adhesive Custom Logo Nameplates Self-Adhesive Aluminium Tags and Stickers |

|||

| Material |

Most metallic materials including aluminum, brass and stainless steel, alloy,nickel

|

||

| Thickness |

Material thickness from 0.1, 0.2mm, 0.3mm, 0.5mm, 0.6mm, 1mm, 1.5mm-3mm,

|

||

| Finishing |

Satin, matte, gloss, spun, polished or brushed surface finishes

|

||

| Fasten |

Mechanical fastener, holes, or strong adhesive attachment methods

|

||

|

Serial NO.

|

Printed, stamped or laser engraved serial numbers or barcodes

|

||

| Colors: |

Pantone Matching System, CMYK Full Colors; Anodized black, blue, red, matte silver…etc

|

||

|

Production Time

|

3-5 Working days for samepls, and 5-10 working days for mass production

|

||

Detailed Descrption of Metallic Labels:

- Material: The metallic labels can be made from various metals, including stainless steel, aluminum, brass, or zinc alloy. Each metal offers different properties such as corrosion resistance, strength, and finish.

- Thickness: Metallic labels typically range from 0.1mm to 3mm in thickness. Thicker labels are more durable and resistant to bending or damage.

- Finish: The surface finish of the labels are including options like brushed, polished, matte, or anodized.

- Adhesive: Permanent adhesives used for metallic labels are strong and durable, often designed to withstand harsh conditions. These adhesives can be pressure-sensitive or heat-activated.

- Customization: Logos and designs can be customized using techniques like laser engraving, embossing, debossing, or printing.

- Size and Shape: Custom metal labels can be made in various sizes and shapes to fit different products. Standard shapes include rectangles, circles, and ovals, but custom shapes are also possible.

- Color Options: While the natural color of the metal is common, labels can also be coated or painted in different colors to match your brand aesthetics. Options include gold plating, black nickel, and colored enamels.

- Durability: These metallic labels are designed to be long-lasting and resistant to environmental factors such as moisture, UV light, and temperature fluctuations.

- Attachment Methods: In addition to adhesive backing, metallic labels can also be attached using rivets, screws, or welding for extra security, especially in industrial applications.

- Edge Treatment: The edges of the metallic labels can be smooth or beveled to prevent sharp edges that could cause injury or snagging on clothing. This adds to the safety and aesthetic appeal of the metallic labels.

Why you choose the metallic labels from chinaprintinggroup?

- Durability: Made from robust materials like stainless steel or aluminum, these labels withstand harsh conditions, including moisture, UV exposure, and physical abrasion, ensuring longevity and sustained brand visibility.

- Professional Metallic Finishing: The metallic finish offers a high-end, professional look, enhancing the perceived value of the products they are attached to and making a strong impression on customers.

- Customized Labels: There are various options for various shapes, sizes, colors, and finishes. These metallic labels can be customzied to meet any of your specific branding requirements, in order to get a unique and recognizable brand identity.

- Strong Adhesion: The permanent adhesive used in these labels provides a secure attachment to various surfaces, preventing peeling or falling off, even in challenging environments.

- Widely used: Suitable for a wide range of products, from electronics and machinery to fashion items and luxury goods.

- High Technics: Laser engraving and embossing allow for high-detail reproduction of logos and designs.

- Resistance to Chemicals: These metallic labels are resistant to many chemicals, which are ideal for use in industrial or laboratory settings.

- Temperature Tolerance: Metallic labels are suitable for products that are exposed to high or low temperatures during use or storage.

- Security Features: Our custom metallic labels can incorporate security features like unique serial numbers, QR codes, or tamper-evident designs.

- Eco-Friendly: Metals like aluminum can be recycled, if you’re looking for a ec-friendly labels,then these labels are a great option.

Which places can be used if I do these metallic labels from your company?

- Electronics: Use on electronic devices and components to provide branding, model numbers, and compliance information. The durability ensures the labels remain intact throughout the product’s lifecycle.

- Industrial Equipment: Heavy machinery and tools, providing essential information such as safety warnings, operating instructions, and company branding that withstands tough working conditions.

- Automotive: Apply to vehicle parts and accessories for branding, part identification, and compliance with industry standards. These labels can endure the high temperatures and exposure to various fluids.

- Luxury Goods: Enhance high-end products like watches, jewelry, and handbags with elegant, custom metal labels that emphasize quality and brand prestige.

- Appliances: Suitable for household appliances, offering a durable labeling solution that remains readable and intact through years of use and cleaning.

- Fashion Industry: Used on clothing, footwear, and accessories to provide a sophisticated brand label that stands out and adds a touch of luxury to the products.

- Packaging: Incorporate into packaging for high-value items to reinforce brand identity and provide a tamper-evident seal, assuring customers of product authenticity.

- Promotional Items: Attach to promotional products like custom merchandise, gifts, and giveaways, ensuring your brand stays visible and associated with quality.

- Furniture: Suitable for furniture pieces, providing a lasting brand mark or certification label that withstands regular use and cleaning.

- Sports Equipment: Used on sports gear and equipment to provide durable branding that can withstand rough handling, exposure to the elements, and frequent use.

How to finish my metallic labels order from ordering to delivery?

- Design and Approval

- Material Selection and Cutting

- Surface Treatment

- Edge Treatment

- Digital Mock-Up

- Quality Control

- Packaging and Shipping

- Design Finalization: Assisit with you to finalize the design, including the logo, text, shape, size, and finish.

- Choose the best application for the design:Laser Engraving: For detailed logos and text, use laser engraving to etch the design onto the metal surface.

Embossing/Debossing: Create raised or recessed designs for a tactile effect.

Printing: Apply color designs using screen printing, UV printing, or other suitable methods.

- Material Recommendation: Recommend the appropriate metal based on your needs (e.g., stainless steel, aluminum, brass).

- Cutting the Metal:

Laser Cutting: Use laser cutting machines for precise shapes and intricate designs.

Stamping/Die-Cutting: For larger production runs, stamping or die-cutting can be used for efficiency. - Surface Treatment:

Cleaning: Clean the metal surface to remove any oils or contaminants.

Polishing/Brushing: Apply the desired surface finish (polished, brushed, matte, etc.). - Edge Treatment:Smoothing/Beveling: Smooth or bevel the edges to remove any sharpness and enhance the appearance.

- Adhesive: Choose a high-strength permanent adhesive suitable for the application surface.

- Digital Mock-Up: Create a digital mock-up for your approval, ensuring all design elements are correct and accurate.

- Equipment and Materials Needed:

Laser Cutting Machine

Stamping/Die-Cutting Machine

Laser Engraving Machine

Polishing/Brushing Tools

Screen Printing/UV Printing Equipment

Adhesive Application Tools

Quality Control Instruments (e.g., calipers, adhesion testers) - Quality Control:

Inspection: Conduct a thorough inspection of each label to check for design accuracy, finish quality, and adhesive application.

Testing: Test the labels for adhesion strength, durability, and resistance to environmental factors (e.g., moisture, UV light, chemicals). - Packaging:

Protection: Pack the labels carefully to protect against scratches and damage during transportation.

Labeling: Clearly label the packages with product details and handling instructions. - Shipping:

Logistics: Arrange for shipping using reliable logistics partners to ensure timely delivery.

Tracking: Provide tracking information to the client for transparency and assurance.

FAQ

1. What materials are available for metallic labels?

- Our metallic labels can be made from a variety of metals, including stainless steel, aluminum, brass, and zinc alloy. Each metal offers unique properties such as corrosion resistance, durability, and aesthetic appeal.

2. How durable are these metallic labels?

- Metallic labels are highly durable and designed to withstand harsh conditions. They resist corrosion, abrasion, and exposure to chemicals, UV light, and extreme temperatures. This makes them suitable for both indoor and outdoor applications.

3. What customization options are available for metallic labels?

- We offer extensive customization options, including different shapes, sizes, and finishes (brushed, polished, matte, anodized). You can also choose from various design techniques like laser engraving, embossing, debossing, and color printing to create intricate and precise logos and text.

4. How strong is the adhesive used on these labels?

- The adhesive used on our metallic labels is a high-strength permanent adhesive designed to provide a secure bond to various surfaces. It ensures that the labels remain firmly attached even under challenging conditions, preventing peeling or detachment.

5. What surfaces can the metallic labels be applied to?

- Our metallic labels can be applied to a wide range of surfaces, including metals, plastics, glass, wood, and painted surfaces. The adhesive is versatile and strong enough to adhere to both smooth and textured surfaces.

6. Are there any special care instructions for maintaining the appearance of metallic labels?

- To maintain the appearance of metallic labels, avoid using abrasive cleaners or harsh chemicals directly on the label. Cleaning with mild soap and water or a soft cloth is usually sufficient. The labels are designed to withstand regular cleaning and handling without degrading.

7. Can metallic labels be used in high-temperature environments?

- Yes, metallic labels are suitable for high-temperature environments. Depending on the metal and adhesive used, our labels can withstand extreme temperatures, making them ideal for applications in automotive, industrial, and outdoor settings.

8. How are the edges of the metallic labels treated to ensure safety?

- The edges of our metallic labels are treated through processes like smoothing or beveling to remove any sharpness. This ensures the labels are safe to handle and do not pose any risk of injury or damage to the products they are applied to.

9. What is the typical production lead time for custom metallic labels?

- The production lead time for custom metallic labels varies based on the complexity of the design and the size of the order. Generally, it takes about 1-2 weeks from design approval to final production. Rush orders may be accommodated upon request.

10. Can you provide samples of metallic labels before placing a bulk order?

- Yes, we can provide samples of metallic labels to help you evaluate the quality, design, and adhesion properties before placing a bulk order. Please contact our customer service team(sales@chinaprintinggroup.com to request samples and discuss your specific requirements.

Related products

Tags Labels and Stickers Printing

Tags Labels and Stickers Printing

Foam Stickers Printing

Tags Labels and Stickers Printing

Tags Labels and Stickers Printing