Custom Logo to Sticker Printing Free Sample MOQ is only 1pc

Send InquiryCustom logo to sticker printing service offers brand’s logo into custom-made stickers, as a unique and effective way to promote your brand.

Custom Logo to Sticker Styles and Sizes for All the Statement You Can Think of

Due to the unique nature of self-adhesive logo to sticker printing, narrow-web flexographic printing equipment has distinctive advantages over letterpress and other types of flexographic printing equipment. Narrow-web flexographic printers are not only easy to operate, but they also offer high-quality logo to sticker printing, high operational efficiency, strong versatility, and the ability to produce a wider variety of products, making them more competitive.

- The surface gloss, color consistency, and density uniformity of the face material determine the ink absorption uniformity of the self-adhesive material, and also affect the color variation among labels from the same batch. The coating strength of the face material determines whether a significant amount of paper dust will be produced during printing and is an important indicator of print quality.

- The uniformity and strength of the backing paper and face material are not only crucial for printing performance but also key factors determining the uniformity of die-cutting and the speed of waste removal and edge breakage during paper feeding. If these indicators are too low, the label machine will not be able to operate at high speeds.

- Whether for single-sheet logo to sticker printing or roll printing, the flatness of the material determines whether the paper can be fed correctly, run smoothly, register accurately, and be collected properly. For roll materials, the uniformity of the rewind tension plays a significant role in the flatness of the roll end face, whether adhesive seepage occurs, and whether accurate registration is achievable.

- The uniformity and correct amount of adhesive and silicone oil application affect the peel strength (release force) between the self-adhesive logo to sticker and the backing paper, which directly impacts the die-cutting waste removal and machine speed. The peel strength also determines the label dispensing condition, that is, its application. Furthermore, the amount of adhesive applied also affects the adhesive seepage at the material end face. Therefore, when purchasing self-adhesive logo to sticker printing materials, it is important to carefully inspect and choose those with appropriate amounts of adhesive and silicone application.

Specifications:

|

Product Name

|

Custom Stickers UV Resistant Printing Durable Waterproof White Vinyl PVC Self-Adhesive Die Cut Logo Stickers |

|

Artwork Format

|

AI,CDR,PDF format

|

|

Size

|

Custom Size Accepted

|

|

Packing

|

Standard Packing Corrugated Carton

|

|

Sample time

|

2-3 Days

|

|

Surface finishing

|

Glossy/Matte/Hologram

|

|

Logo

|

Accept Customized Logo Printed

|

|

Color

|

Partone Color +CMYK

|

|

Payment

|

T/T,Western Union,Paypal

|

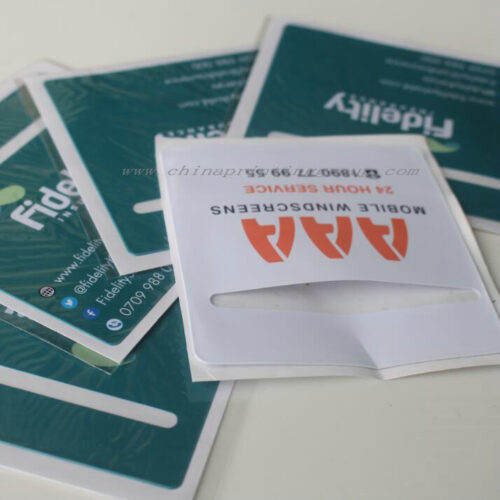

Free Design of Custom Logo to Sticker Any Size,Shape & Qty

Packaging: on roll or sheet.

Printing: Full color or Pantone color printing.

Finishing: can be glossy or matte lamination, spot UV, waterproof, embossing and foil stamping, etc.

MOQ: No Minimum order Quantity. Small order short runs acceptable.

Custom: Custom design of printing layout is available.

How to prepare your design and artwork for logo to sticker printing:

1. Design Principles:

- Start with a clear and concise design.

- Logo to stickers are typically small, so your logo or message needs to be legible at a reduced size.

- Use bold lines and limit the amount of text to improve readability.

2. Color Considerations:

- Use CMYK color mode for printing, as it provides the most accurate color reproduction.

- Be aware of how colors might look different when printed compared to a digital screen.

- Tools like Adobe Express offer a range of color options and adjustments to get your colors just right.

3. Resolution and File Format:

- Ensure your design of logo to sticker is at a high resolution (300 DPI or higher) to avoid any pixelation or blurriness.

- Preferred file formats are typically PDF, AI, EPS, or high-resolution PNG or JPG files.

- Make sure that the details of your design for logo to sticker is crisp and clear when printed.

4. Bleed and Safety Zones:

- Include a bleed area (extra space around the edge of your design) to avoid any design elements being cut off during the printing process.

- Similarly, keep all critical elements within the safety zone to ensure they aren’t trimmed during the cutting process.

5. Choosing the Right Software:

- Use professional design software like Adobe Illustrator or Photoshop for more control over your design.

6. Proofreading and Final Checks:

- Before finalizing your design for logo to sticker, make sure to proofread all text and review all design elements.

- It’s advisable to get a second pair of eyes to look over your design to catch any potential errors.

Logo to Sticker Custom Printing Service, Make Your Logo Outstanding.

- Custom sticker printing is a dynamic way to bring your logo to life.

- These stickers can serve multiple purposes, from being a part of your packaging solution to acting as a marketing tool at events or in guerrilla marketing campaigns.

- The process involves converting digital logo designs into physical stickers, which can be customized in various sizes, shapes, and materials.

Key Features

- Customization:

One of the main appeals of this service is the high level of customization it offers.

You can choose from a range of sizes, shapes (like standard circles, squares, or custom die-cuts), and types (such as vinyl, holographic, matte, or glossy finishes). - Quality and Durability:

These services often use high-quality materials and printing techniques.

This ensures that stickers are not only visually appealing but also durable, able to withstand environmental factors like sunlight and rain. - Versatility in Usage:

The stickers can be used on a variety of surfaces including laptops, water bottles, car bumpers, and storefronts.

This versatility makes them an excellent tool for branding and personal expression. - Digital Proofing and Previews:

Many services offer digital proofs, allowing you to preview and make changes before the final printing.

This ensures that the final product meets your expectations. - Fast Turnaround and Global Shipping:

Chinaprintinggroup offers quick production times and international shipping, making it easy to get your custom stickers no matter where you are located.

Used for:

- Business Branding: Custom stickers featuring a company logo are a cost-effective way to increase brand visibility.

- Personal Projects: Ideal for individual creators looking to add a personal touch to their belongings or projects.

- Event Promotion: Useful for handing out at trade shows, conferences, or community events to spread brand awareness.

- Marketing Campaigns: Effective in guerrilla marketing tactics, as they are easy to distribute and can leave a lasting impression.

With high customization, quality, and versatility, these stickers can play a significant role in your marketing strategy or personal expression, making your logo memorable and visible in everyday settings.

6 Steps to order your logo to sticker printing services

Step 1: Design Preparation

- Logo Submission:

The process starts with submitting your logo.

This can be an existing company logo or a new design created for a specific purpose. - File Format and Quality:

Ensure the logo is in a high-resolution format (preferably vector formats like AI, EPS, or PDF) for clear and sharp printing results. - Design Adjustments:

Depending on the sticker’s intended use, you might need to make adjustments to the logo, such as resizing or adding additional text or design elements.

Step 2: Customization and Specification

- Choosing Size and Shape:

Decide on the size and shape of the logo to sticker.

Our custom printing services offer a range of shapes like round, square, rectangle, or custom die-cut shapes that contour around the logo. - Material Selection:

Select the material for the sticker.

Options often include vinyl (for durability and weather resistance), paper (for indoor use), or specialized materials like clear, holographic, or metallic. - Finish Options:

Choose from finishes like glossy, matte, or UV-coated, depending on the appearance and durability required.

Step 3: Proofing and Confirmation

- Digital Proofing:

Our services provide a digital proof of your logo to sticker.

This is a crucial step to review the design, color, size, and shape before it goes into printing. - Revisions:

Request revisions if necessary. It’s important to get the design just right to avoid costly mistakes.

Step 4: Printing and Production

- Printing Process:

The stickers are printed using advanced printing technology.

Digital printing is common for its precision and color accuracy. - Cutting and Finishing:

The stickers are then cut according to the selected shape.

This could be a standard cut or a custom die-cut that follows the logo’s outline.

Step 5: Quality Check and Packaging

- Inspection: Post-printing, each logo to sticker is inspected for quality assurance, ensuring that every detail aligns with the proof approval.

- Packaging: The stickers are then packaged and prepared for shipping. Packaging often depends on the sticker type and quantity.

Step 6: Delivery and Use

- Shipping:

The final product is shipped to you. Delivery time can vary based on the location and shipping method.

3-5 days by express usually. - Application:

Once received, these logo to sticker can be used for various purposes, including your brand promotion, product labeling, giveaways, or personal use.

Additional Services

- Design Assistance:

Our custom design services offer design support for clients who need help with logo creation or adjustments. - Sustainability Options:

Eco-friendly printing options are available for environmentally conscious clients, including recyclable materials and soy-based inks. - With an emphasis on customization, quality, and customer service, make it easy to transform logos into impactful marketing tools or personal labels.

FAQ:

1.What is the minimum order quantity for custom logo to sticker printing from www.chinaprintinggroup.com?

1pc only.

2.How long does it usually take to receive custom stickers?

Usually it’s about 1 week for overseas shipment.

3.Can I get a sample before placing a large order?

Absolutely yes.

4.What are the differences between die-cut and kiss-cut stickers which is logo to sticker type?

The difference is separate one of the stickers or many stickers together on a sheet.

5.How do I ensure my stickers are weatherproof?

You can test it when you put it in water.

6.Can I print stickers with metallic or holographic effects?

Yes,no problem.

7.What file formats are accepted for sticker designs?

PFD,JPG,AI,PSD…etc

8.Is it possible to print stickers with transparent backgrounds?

Yes, transparent stickers are available.

9.How can I ensure the colors in my design print accurately?

We make sample for color checking before bulk production.

10.What are some eco-friendly options for logo to sticker printing?

Recycled paper stickers are eco-friendly,and we have soy ink which is food grade.

Related products

Tags Labels and Stickers Printing

Tags Labels and Stickers Printing

Serial Number Stickers Vinyl Sticker Sheets Labels Silver Foil Custom Matt Foil Stickers

Foam Stickers Printing

Tags Labels and Stickers Printing

Stickers With Logo 4 Color Static Cling New Window Labels Custom Reverse Printed No Glue

Car Decals Printing

New 100% Vinyl Sticker Paper Custom Decal With Free Shipping

Tags Labels and Stickers Printing

Sticker Sheets Custom PVC Self-Adhesive Insurance Car Holders Pocket Stickers Printing for Banks

Tags Labels and Stickers Printing

Tags Labels and Stickers Printing