Sticker Label Frosted 3M Adhesive Cheap Graphic Overlay

Send Inquiry-

Use:

-

mobile phone accessories, Mobile Phone, Speakers, Camera, Earphone, Smart Watch, Smart Electronics, Home Appliance, COMPUTER, Projector, Other Consumer Electronics

- Color:

-

CMYK Color PMS Spot Color

- Size:

-

Customized Size

- Surface finishing:

-

Lamination

- Printing:

-

Offset Silkscreen Printing UV Printing

- Adhesive:

-

Permanent or Removable

- Certification:

-

ISO9001

Sticker Label Custom Frosted Label or Sticker Printing High Quality Polyester Graphic Overlay

- Polyester Graphic Overlays Waterproof, scratch resistant and UV resistant sticker label.

- Polyester graphic overlays (PET Graphic Overlays) are strong, durable.

- Recommended for membrane switches, especially when embossing is involved, such as keyboards and keypad switch overlays.

- Hot Sale Low Price Silk Screen Frosted PVC Switch Panel Overlay Panel Sticker label

- Custom plastic waterproof frosted packaging label PC button panel die cut silk screen stickers roll for electronic products

- Custom Design Screen printed pre-cut adhesive Lexan polycarbonate graphic front panel label overlay

- Custom Shape Printing Plastic PC Frosted Surface Waterproof Lightfast Clear Acrylic Sticker Overlay Label Maker

Specifications:

|

Product Name

|

Custom Frosted Label or Sticker Printing Polyester Graphic Overlay High Quality Custom Printed

|

|||

|

Material

|

Frosted PVC / Glossy PVC

|

|||

|

Design/Shape/Size

|

Any Designs & Shapes & Size are available

|

|||

|

Artwork format

|

PDF, AI, EPS, CDR, PSD, JPG(the resolution is >300dpi)

|

|||

|

Surface Finishing

|

UV varnishing, Lamination, Foil hot stamping, Embossing, etc.

|

|||

|

Certification

|

ISO9001, SGS, ROHS, UL

|

|||

|

Transportation

|

DHL, FedEX, UPS, TNT, Air Transport, Sea Transport, etc.

|

|||

|

Feature /Application

|

Waterproof, UV-resistant and practically unscruffable

|

|||

Sticker Label Self-adhesive Label Custom Logo Sticker High-grade Frosted Stickers Usages

- Sticker label polycarbonate graphic panels,

- Custom polycarbonate panels,

- Polycarbonate front panels,polycarbonate control panels.

- Frosted surface polycarbonate graphic panels are made from high quality polycarbonate material and provided with 3M adhesive for perfect and long lasting bonding.

- Sticker label are printed on the subsurface, so the inks are protected from scratches, scuffs and fading.

- Long service time, applied with heavy high tack adheisve, works on challenging materials, like tires, fabrics, and bumpy plastics,waterproof, UV-resistant and practically unscuffable

Polycarbonate Graphic Panels Applications

- Polycarbonate (Lexan, PC) film is a high quality, tough, stable and heat-resistant material ideally suited to a number of graphic and industrial applications.

- Superior mechanical strength, toughness and clarity.

- Anti-high temperatures, chemical abrasions resistant and corrosion resistant.

Poly sticker label graphic panels are commonly used as

- Faceplates,

- Membrane switches or decorative features for control panels,

- Food equipment,

- Instrumentation,

- Kitchenware labeling,

- Auto industry,

- Consumer appliances,

- Weighing scale,

- Telecommunications equipment,

- Automobiles,

- Instrumentation,

- Computer hardware,

- Digital device labeling,

- Medical field,

- Automotive,

- Electronics,

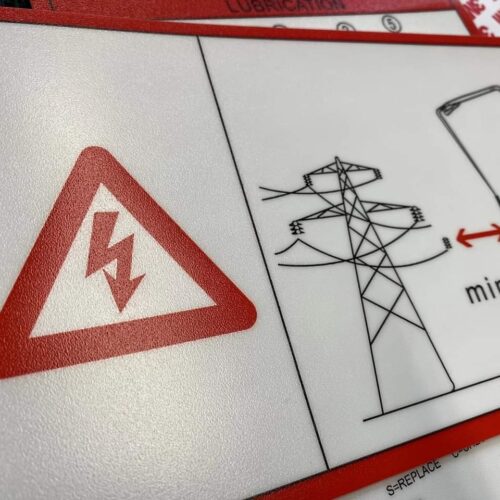

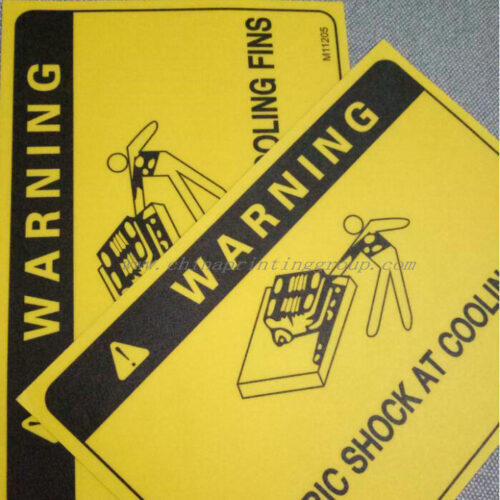

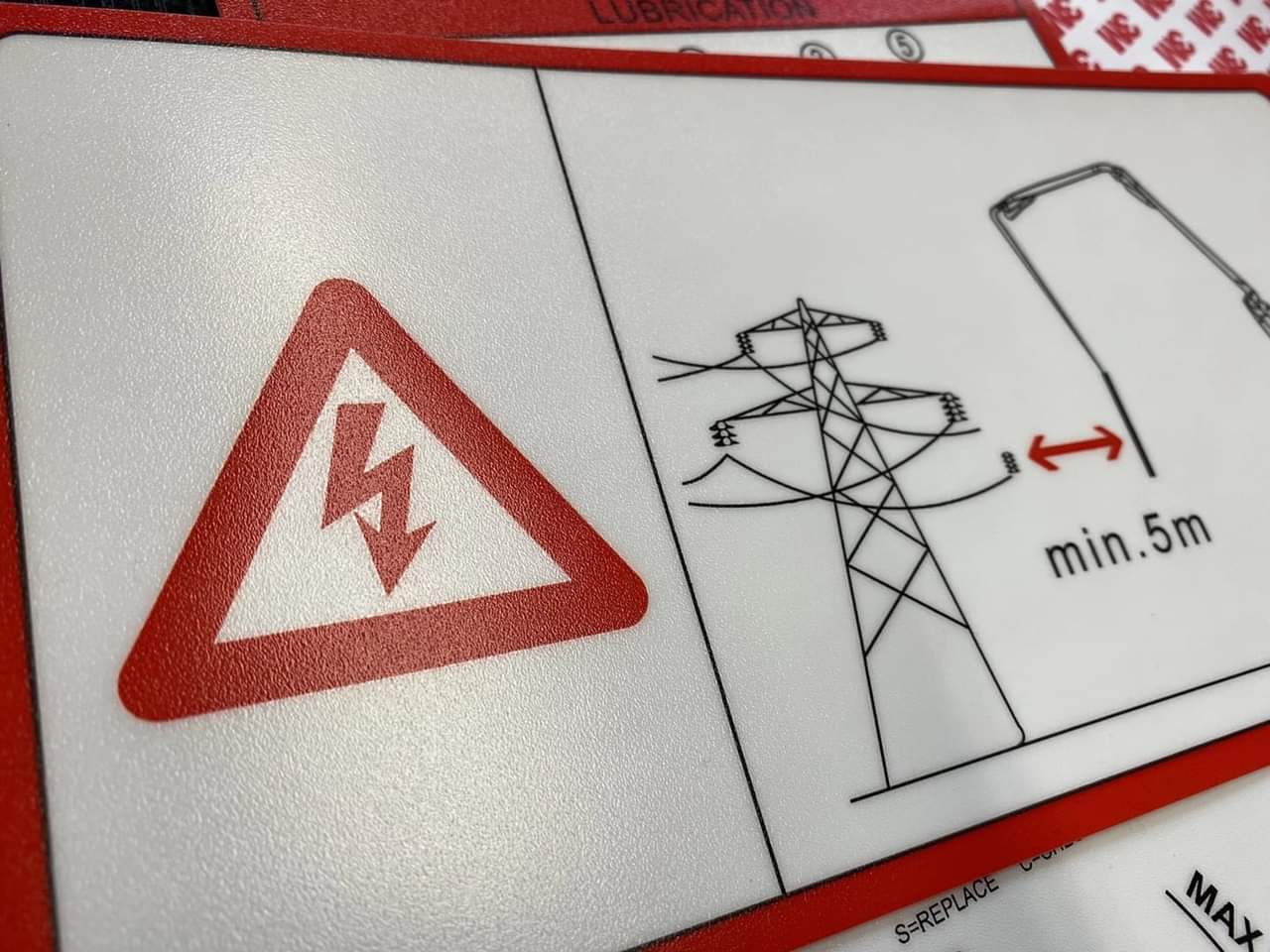

- Warning labels for industrial machinery or hazardous locations,

- Military equipment,

- Aircraft,

- Airlines and numerous other applications.

Custom Printed Sticker Label Poly Graphic Panels

We provide a wide range of Polycarbonate Graphic Overlays that are manufactured from premium quality polycarbonate including:

- Quick turn graphic overlays,

- Graphic overlay prototyping,

- Polycarbonate Graphic Overlays & Faceplates,

- Digital Graphic Overlays,

- Screen Printed Graphic Overlays,

- Polycarbonate Control Panel Overlays,

- Polycarbonate Sticker Labels.

High quality, long-lasting Polycarbonate Overlays, Faceplates and front panels produced from Polycarbonate materials, cut to your exact sizes and printed.

Tips you must know the customization and usage of panel overlay for surface stickers

- In our daily lives, panel overlay stickers can be seen everywhere:

the shell of a refrigerator, the surface of a microwave, the buttons of a washing machine, the shell of a remote control, the surface of an air conditioner… - The application range of surface stickers is very wide, and they have great effectiveness in various industrial and household appliance products. Such as intelligent electronic measuring instruments, medical instruments, computer control, CNC machine tools, electronic scales, copiers and refrigerators, microwaves, washing machines, etc.

- Panel stickers are very important for these devices, so when customizing and using them.

We must know these precautions in order to make our face stickers more practical, more fitting to the equipment, and play a maintenance role.

Choose the materials for the overlay sticker label

- When customizing overlay stickers, it is very important to choose the appropriate materials.

Overlay sticker labels are made of various flexible plastic materials such as PVC, PET, PC, etc., each with different properties. - PET material has good transparency, high glossiness, strong corrosion and wear resistance, excellent mechanical properties, and excellent insulation performance;

- PC material has a thinnest thickness of 0.03mm, with good comprehensive indicators of physical and chemical properties, high temperature resistance, strong processing adaptability, and can be divided into sand and smooth surfaces.

The frosted surface is not affected by light interference and can also mask scratches.

The smooth surface has bright colors and strong decorative properties; - PVC material has good ductility, strong chemical corrosion resistance and insulation performance, and can also be divided into smooth and sand surfaces.

Cold pressing can be used to process three-dimensional graphics and text. - In addition, when customizing surface stickers, we also need to choose different types of double-sided adhesive according to the material of the surface sticker, so as to better fit the equipment and avoid bubbling, detachment, and other phenomena.

Customized style for surface sticker label

- After selecting the materials, the next step is also very important. We need to customize suitable surface stickers according to the panel of the equipment.

- When there is a display window on the surface of the device:

The edge of the window where the background color of the customized surface sticker is located must be smaller than the window to avoid window leakage; - If the buttons of the device have contour lines, a line width between 0.5mm-0.75mm should usually be selected. If it is too small, it is not aesthetically pleasing;

- The size of the surface mounted buttons should usually not be less than 10mm, and the protrusion height of the buttons should be between 0.4mm-0.6mm.

- The position should start from the inner edge of the device’s button contour line, so that the touch of the buttons is more prominent and three-dimensional.

- Remember, we must customize the surface sticker according to the style of the device panel in order to provide the best maintenance effect.

Find the right method to use layout sticker label

- After customizing the sticker labels, it is necessary to stick them onto the device in order to truly complete the task.

- Before applying surface sticker label to the device, we need to gently wipe the surface or curved surface with paper or a dry towel to ensure that the surface is flat, smooth, and free of bumps or dust adhering to it.

- After wiping, we need to remove the double-sided tape on the back of the sticker and center it quickly and accurately onto the surface of the device, to ensure that the sticker is free of bubbles.

- If we want to replace the surface sticker, we need to use a hot air gun or other items that can reach a temperature of 150-160 ℃ to blow hot air.

- Heat the surface sticker that needs to be replaced with hot air, preferably between 10-15 seconds. After cooling, peel it off to the maximum extent possible

We can produce your custom Polycarbonate Overlays, including:

- Polycarbonate Front Panels,

- Polycarbonate Warning Stickers,

- Polycarbonate Stickers,

- Polycarbonate Keyboard Stickers,

- Polycarbonate Overlays,

- Lexan Polycarbonate Control Panel Overlays,

- PC Overlays,

- Polycarbonate Labels,

- Polycarbonate Digital Weighing Scales Graphic Overlays,

- Screen Printed Polycarbonate Graphic Panels,

- Digital Printed Polycarbonate Control Panels,

- Full Color Printed Polycarbonate Front Panels.

Thickness of Polycarbonate Graphic Panels

From 125 microns to 760 microns. Commonly used is 250 microns thickness.

Printing Methods

- Silk Screen Printing,

- UV Digital Printing or UV Offset Printing.

- PC Graphic Overlay Printing can be done with digital, screen-printing, or a combination of printing processes.

Back Adhesive

3M. Adhesive or selective adhesive.

Finishes

- Polycarbonate Front Panels are available in a clear, velvet, brushed and embossed.

- The more common choice is the velvet finish which is excellent for hiding surface scratches.

- Texture or selectively textured finishes can be added to the surface of an Polycarbonate Control Panels.

Windows

- Transparent Windows for Displays or Indicator Lights, Adhesive-free Windows, Tinted Windows.

- No MOQ (Small Order Prototyping Acceptable) and Fast Turnaround (4-6 Working Days).

- We provide Clear Glossy Polycarbonate Control Panels and Velvet

- (Matte) Textured Polycarbonate Front Panels Silk Screen or Digitally Printing Services.

- All of Polycarbonate Overlays can be custom printed according to your specifications.

Quick Turnaround of Sticker Label Overlay Printing

- We can deliver rapid sticker label graphic overlays as quickly as 2 business days after prototype design approval.

- We has the technology and equipment to provide your business with small runs of quick turnaround graphic overlays.

- Typical turnaround of standard ordering is 5-7 working days.

- If you are in need of quick turnaround sticker label printing, PC faceplates and PC nameplates prototyping in small runs, just tell us your delivery requirements, and we’ll work with you to meet your delivery date.

PACKAGING & SHIPPING

FAQ:

we can pack the goods in your branded boxes with printing logos and information after getting your authorization emails.

2. What is your terms of payment?

A:We accept 30% payment before production as deposit, and 70% balance once all goods are ready against delivery. We’ll show you the photos of the products and packages before balance payment arrangement.

3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU….etc

4. How about your delivery time?

A: Generally, it will take 5-7 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

6. What is your sample policy?

A:We can supply the sample for free if you just need to see our previous works for reference, but the samples sending courier cost need to be paid by your side.

7. Do you test all your goods before delivery?

A: Yes, we have 100% quality test for each item one by one before delivery.

Related products

Frosted surface labels printing

Vinyl Print Stickers PVC Waterproof Frosted Label or Sticker Printing Custom Design and Logo

Frosted surface labels printing

Custom Shape Sticker Sizes Circle Label Printing Plastic Frosted Surface Waterproof UV Resistant